HDS-18E

Incredible Truck Lift for Heavy-Duty Lifting

BendPak's HDS-18E four-post lift is engineered to make light work out of heavy lifting. It’s built to last and features upgrades that increase safety, durability and productivity. This is the lift that graduates from the class of mid-size trucks, vans and SUVs up to heavy-duty applications. This is a professional car lift that can even handle some industrial and farming equipment. It’s also lighter-duty than other lifts in the truck-weight category, so it’s not overkill when you don’t need, for instance, 20 tons of lift capacity when 9 tons will do just fine.

Extended runways

To accommodate long wheelbases, the HDS-18E offers extended runways that are 263" front-to-back. This is the first of the heavy-duty models to offer extended runways. All 27K, 35K and 40K lifts are built this way. Better-gripping runways ensure the massive tires on your massive vehicles stay put. If the runways gets slick, their treaded surfaces are still able to grab the wheels without damaging or marring them.

Large base plates

12" x 12" base plates don’t just provide a solid foundation, they inspire the confidence to work on virtually any-size vehicle up to the rated weight capacity.

Dual-hub cable sheaves

Supersized 12" diameter cable sheaves within the runway and cross tubes, combined with massive 4" diameter sheave axles, dramatically improve cable wear and critical component lifespan, meaning this car lift increases your safety, so you spend less money in service-related expenses down the road.

Heavy-duty aircraft cable

The HDS-18E four-post lift features four galvanized lifting cables that do an excellent job of providing abrasion resistance and preventing fatigue.

Built-in lubrication

Grease nipples are located on every sheave and sheave axle to make lubrication maintenance a breeze.

Spring-loaded safety locks

Spring-loaded safety locks automatically engage continuously during rise, and adjustable safety ladders allow for precise runway leveling, even if the posts have been installed on slightly sloped floors.

Push-button pneumatic lock release

A simple push-button pneumatic lock release makes lowering operations simple and fast. Aircraft-quality stainless steel and aluminum pneumatic cylinders will provide years of trouble-free service.

Secondary lock system

A secondary lock system is on constant guard and acts as a slack-cable device in the unlikely event of an unexpected cable failure. Only consider a four-post lift that offers this secondary lock system.

Integrated design

Lifting cables, airlines, safety latches and sheaves are all fully enclosed within the structure.

Adjustable height locking positions

Features adjustable locking positions for variable-height parking and infinite leveling.

Electric-hydraulic power system

A maintenance-free electric-hydraulic power system assures ultimate dependability. Despite its size and lifting capacity, all controls on the HDS-18E four-post lift are conveniently located within easy reach.

Optional rolling bridge jack (two makes a set)

Rolling jacks are used to raise the front or rear portion of a vehicle off the car lift’s runways, allowing operators to perform efficient wheel and brake service. A pair of jacks allows the entire vehicle to be elevated. Each jack has telescoping arms and frame contact pads that can be extended over the runways and positioned under vehicle lifting points. Each jack features three safety-lock positions and stackable truck and van adapters for increased lifting height and better access to frame contact points on high ground-clearance vehicles. The jacks come equipped with a commercial-grade air-hydraulic pump.

- 18,000-lb. lifting capacity

- CE Approved and Certified. Meets or exceeds the standards prescribed by European Standard EN-1493

- Supersized 12" diameter cable sheaves

- Galvanized lifting cables

- Grease nipples

- Single hydraulic under-runway cylinder

- Integrated flow restrictor

- Durable powder coat

- Spring-loaded safety locks

- Second lock system on constant guard

- Fully enclosed lifting cables

- Multiple adjustable height locking positions

- Maintenance-free electric hydraulic power system

- Conveniently positioned operator controls

- 12" x 12" base plates

- Runways feature a durable matte finish

- Optional rolling jacks

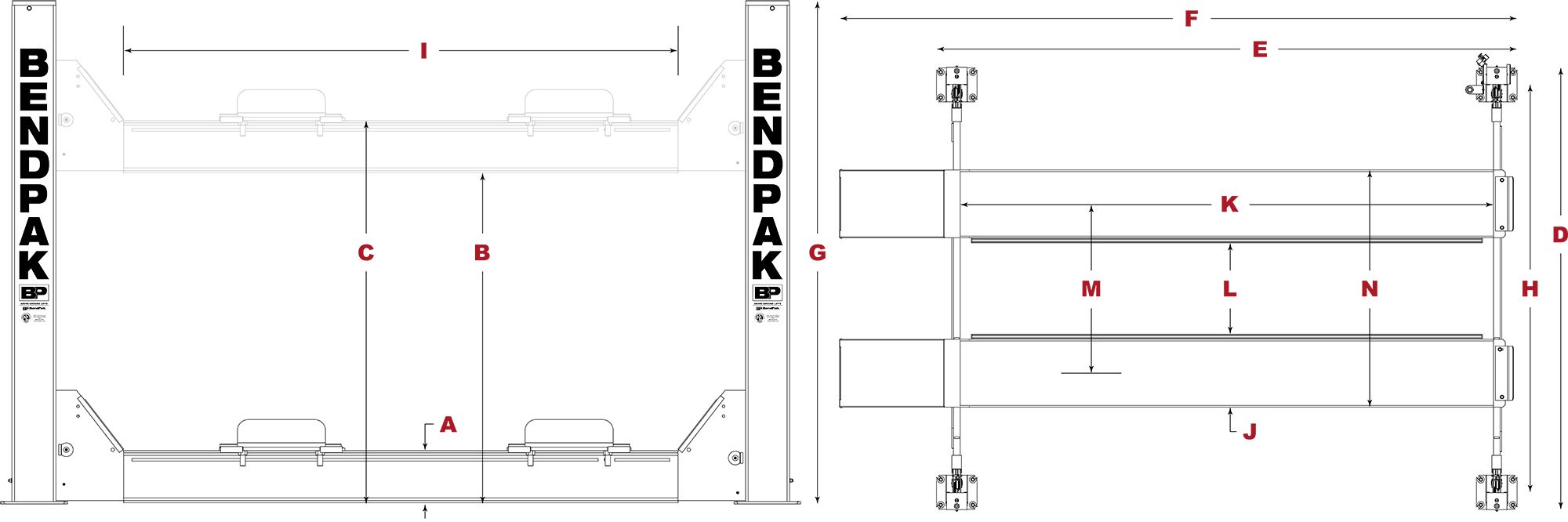

Capacity

Rise

Outside Dimensions

Inside Dimensions

Runways

Minimum Wheelbase

Locking

Power Unit

Shipping

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

Note: Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2017 or ANSI/UL 201. Consult www.autolift.org for a complete list or contact BendPak via contact@bendpak.com.

BendPak lifts are supplied with concrete fasteners that meet the criteria of the American National Standard ANSI/ALI ALCTV-(Current). Buyer is responsible for all charges relating to any special regional structural or seismic anchoring requirements specified by any other agencies or codes such as the Uniform Building Code (UBC) or International Building Code (IBC).

WARNING: California Prop 65

-

User Manual

User Manual -

Sales Sheet

Sales Sheet -

Warranty

Warranty

Lift Now,

Pay Over Time

with the Synchrony Car Care™ Credit Card.

Convenient monthly payments make your equipment purchase simple.

Learn More